On the outskirts of Fort Collins, Colorado stands Millhaus. Designed and built by Greg Fisher, who has run a one-man architectural office since 1993, it was erected between 2019 and 2020, and then certified by the Passive House Institute in 2021.

The design of Millhaus takes its inspiration from the history of the area, which was once home to a mill where cherries were processed. Though commercial activity ceased in the early part of the 20th century, the structure that housed the mill is still standing and has since been converted to a single-family residence. Fisher’s home, which sits on an adjacent property, is a new, timber construction and borrows more from the idea of a mill than an attempt to recreate or echo the design of the original building. The three asymmetrical gables bring to mind the purity of the old mill house structure’s construction, while the ambiance of the interior is defined by a mix of natural and industrial materials, including exposed brick, wood, black steel, and concrete. The result is an all-electric, 3,200-ft2 celebration of the area’s historic forms combined with industrial chic aesthetics.

This metaphor extends to the use of specific spaces, as well. As Fisher explains, the tool crib is the heart of any industrial workshop and where tools are secured in storage cages. In the Fisher household, however, it is the pantry that sits at the center of the home and has been enclosed in perforated metal panels and steel columns.

From Principle to Project

Fisher—who both lives and works in the home with his wife—has been active within Colorado’s sustainable architecture community for the majority of his career. Though he began his study of architecture in the 1980s and started his personal practice in 1993, he experienced what he describes as a major shift around the turn of the millennium that broke him out of a kind of thinking that had kept the artistic side of design siloed from the aspects of architecture that concern building science and sustainability. He cites the LEED standard as being his “gateway drug,” which encouraged deeper exploration into evermore rigorous building standards. He eventually came upon the Living Building Challenge; the US DOE’s Zero Energy Ready system; and the Living Environments in Natural, Social and Economic Systems (LENSES) framework, which he assisted in creating with the Institute for the Built Environment at nearby Colorado State University.

A little over a decade ago he was introduced to Passive House.

Though he initially shrugged it off because he thought it was merely an extrapolation from the passive solar principles that first emerged in the 1970s, and about which he learned about in the 1980s, he eventually understood that it was more performance-driven. As he learned more about the standard, he came to a greater appreciation of its rigor with respect to comfort, energy use, airtightness, indoor air quality, and resilience, he says. He also appreciates the clear performance targets set forth in the standard and understands them not only from the perspective of a designer, but also a tradesperson. Several years ago, Fisher became a certified Passive House tradesperson after taking a training course with Colorado-based Emu Systems, and has since served as his own general contractor, framing contractor, air sealing contractor, and trim contractor.

Though Fisher has incorporated the principles of Passive House design into several projects over the years, Millhaus is his first certified Passive House. He began designing the project using designPH and consulting with Emu Systems, taking part in the Emu Passive House Pilot Program. According to Fisher, Emu cofounders Enrico Bonilauri and Mariana Pickering have done a tremendous amount of modeling and analysis to create a builder-friendly program including the fundamental assemblies required for Passive House certification. The assemblies can then be adjusted based on climate zone.

Compared to climate zone 7, Fisher says his zone 5 assemblies were a piece of cake, though they still required significant fine-tuning and tweaking on account of the relative complexity of the design and high surface area-to-volume ratio due to the home’s three gables and the flat roofs between them. It was also difficult to find the balance between performance and the views of Colorado’s majestic landscape.

“The biggest challenge is trying to properly proportion the window openings relative to their exposure, relative to their shading, and relative to the proportion you can have and still achieve the energy performance that you need for Passive House,” he says. This was further complicated by the limited options for shading materials within previous and more primitive versions of designPH (shading materials were either solid or not), but Fisher managed to prevent overheating by relying on overhangs to shade the home’s south-facing windows.

Meanwhile, the home’s triple pane, argon-filled windows round out the envelope. They were manufactured in Colby, Kansas, by Advantage Architectural Woodwork, though the firm sourced their glass from Europe. It was the first instance in which Advantage had used a European glass supplier rather than one based in North America, but the resulting product was higher performing and more affordable even with the increase in shipping costs. Fisher, as well as many others, is hopeful that better domestic glass sources will become available as Passive House grows.

Breathing Easy

Prior to living in a Passive House, Fisher and his wife did not have air conditioning in their house. Instead, they would sleep with the windows open and rely on fans for air circulation. However, during periods of intense fires in the area, leaving anything open was impossible, and the two would have to close their windows and sleep in their relatively cool basement to stay comfortable.

This is no longer the case. Fisher now says that, when distant fires erupt, he may see the haze from his window, but that he can only smell them when he walks outside. Inside, the temperature is pleasant, and the air smells fresh. When he changes the filters on his ERV (a Zehnder Q450), however, they can be caked in ash. Though he believes that his home is not imminently threatened by wildfires at this time, it is clear that even distant fires can have a major impact on indoor air quality and comfort. As fire seasons grow in duration and the areas impacted by fires expand, it seems likely that air filtration and the kind of airtight construction that is central to Passive House design will become more popular in regions where smoke is more of a threat to wellbeing than fire.

The Millhaus Takes Shape

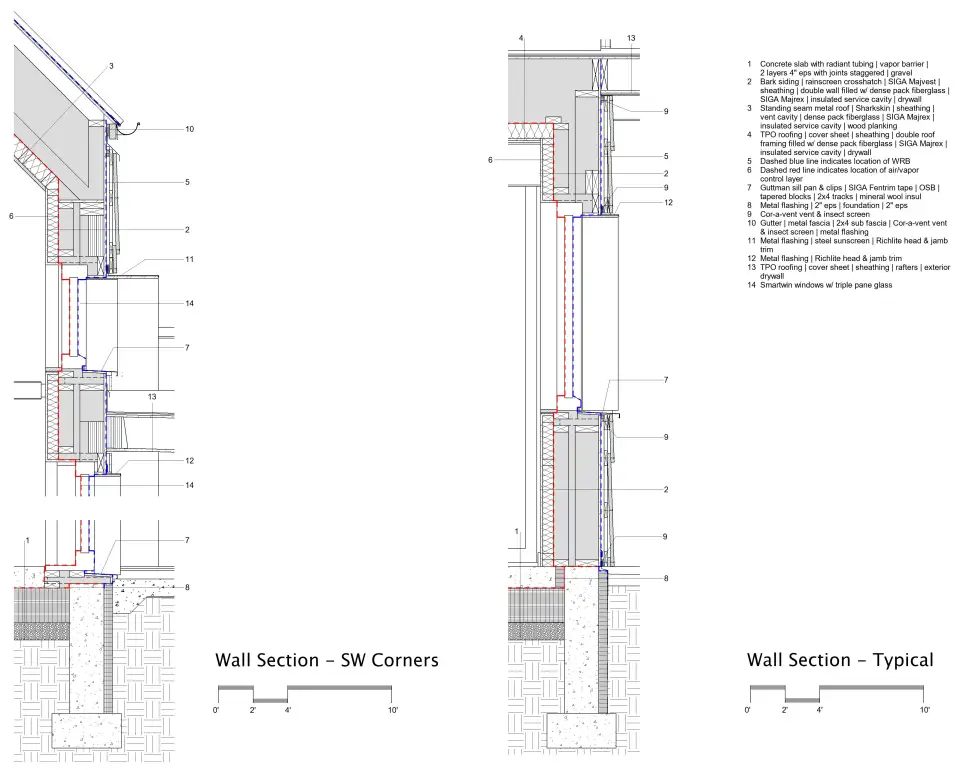

Along the exterior of the foundation is 2 inches of EPS insulation. Another 8 inches of EPS sits below the slab. While the rest of the home is foam-free, below-grade alternatives to EPS were simply too expensive at the time, Fisher says. The below-grade and above-grade control layers on the project are also different. Stego Wrap was used for the former, while SIGA Majrex was the intelligent air and vapor control layer for the walls and the roof.

One of the more unique design features of the project is what Fisher describes as a triple wall, which is a double wall assembly with an additional service cavity. “We have a 2x6 outer wall, a 1.5-inch gap, a 2x4 inner wall, then our vapor and air control layer are on the inside face of the inner 2x4 wall, and then we have a service cavity, where all of utilities can be run and not penetrate the air control layer, inboard from that and is also insulated,” he explains (see Figure 1). This strategy of avoiding unnecessary penetrations is one of the reasons the project was able to achieve a blower door test score of 0.44 ACH50.

The home also boasts some hefty R-values. The average R-value for the walls is around 50, while the roof has multiple conditions: flat and vaulted conditions (R-68) and a more typical vented attic condition (R-92). The primary insulation for both the wall and roof assemblies is blown-in fiberglass, with mineral wool also used in certain areas.

The exterior of Millhaus is accented with industrial materials, including steel and concrete, but its appearance is truly defined by its use of bark. Far more than just an aesthetic feature, the bark is a cradle-to-cradle (or C2C) product, meaning that its core components can be recycled upstream so they can be reused indefinitely or are biodegradable when their lifecycle ends. In this case, the bark is harvested from tulip poplar trees grown in North Carolina in a way that does not disturb the long-term viability of the tree, and it’s then used as cladding on housing. When that phase of the bark’s life has come to an end, it can be safely composted, providing nutrients for the next generation of plants.

Other materials play a functional role, as well, including the concrete floor. In addition to liking the appearance of concrete, the 5-inch slab is both the floor structure and used as the medium for the house’s radiant heating and cooling system, which is supplied by a ground source heat pump. The domestic hot water system for the home also relies on a ground source heat pump, thereby making the home all electric with the exception of a seldom used indoor fireplace and grill.

Given the home’s airtight construction, judicious use of insulation, and electric components, Fisher was able to significantly reduce the energy demand on the project. Given the state’s reliably clear skies, he was also able to achieve net zero source energy with the addition of a 5.8-kW solar array on the roof of the home, making Millhaus not only a reminder of Colorado’s history but a model for its future.

Passive House Metrics:

Heating Energy Demand: 13.9 kWh/m2a (4.40 kBtu/ft2/yr)

Cooling Energy Demand: 12 kWh/m2a (3.80 kBtu/ft2/yr)

Site Energy (PER): 35 kWh/m2a (11.08 kBtu/ft2yr)

Air Tightness: .4 ACH50

Top photo courtesy of Jordan Knight.